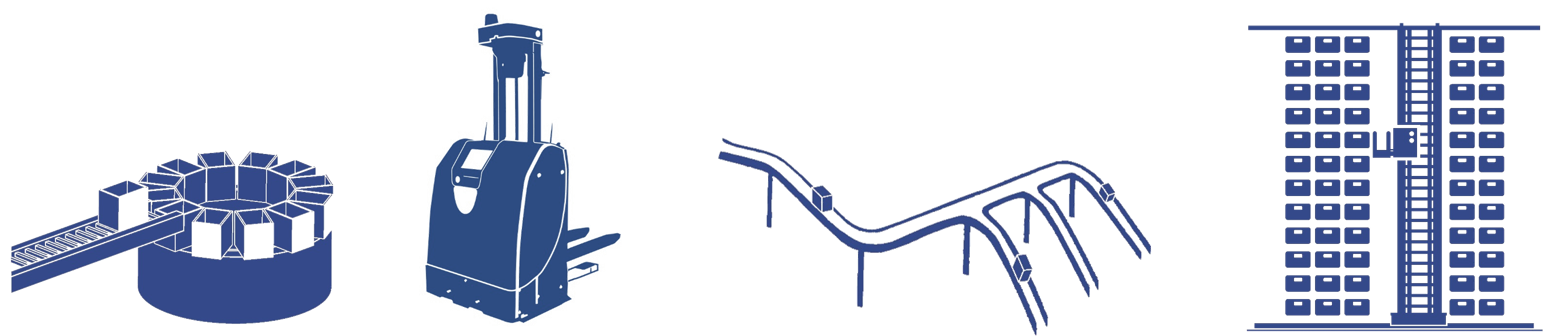

The Intralogistic Systems Product Group addresses both single materials handling products and complete turnkey systems. It focuses on automation, control and IT, and integration of several types of materials handling equipment into one system. It is open to system integrators and suppliers of complete systems (companies signing turnkey contracts). The Product Group covers different types of systems:

- Automated dispatching and order picking systems enable fast and precise management of mail in processing and distribution centres in order to dispatch incoming and outgoing mail to and from a designated service area.

- Automated Guided Vehicles (AGV) enable productivity improvements by optimising the flows of manufacturing processes through autonomous reliable systems.

- Complex baggage transport systems enable baggage to be brought automatically by means of high-tech identification systems to the collecting point of the relevant plane in a very short time.

- Automated storage systems in warehouses enable optimised management of the storage capacity and an efficient use of vertical space (widely used in e-commerce).

Members

The Product Group consists of manufacturers from Austria, Finland, France, Germany, Italy, Luxembourg, the Netherlands, Spain and the United Kingdom.

Companies active in the Intralogistic Systems Product Group

|

|

|||

|

|

|||

|

|

|||

|

||||

|

Objectives

- Provide an international forum to elaborate on technical and business matters

- Develop reliable market transparency on the basis of statistical data received from participants

- Develop technical guidance at European level

- Define interface and communication standards

- Define consistent technical language

Activities

Study on the energy consumption of intralogistic systems

Together with the Karlsruhe Institute of Technology, the IS PG is developing a common measurement method for the energy consumption of intralogistic sub-systems, notably roller conveyors, belt conveyors, chain conveyors, merging and diverting elements, sorting systems, shuttle systems and stacker cranes. It aims to allow benchmarking and comparison of the energy consumption of intralogistic systems and increase the energy efficiency of those systems.

Ecodesign measure on electric motors

We are closely monitoring developments on the review of the ecodesign measure on electric motors, the so-called Lot 30. We participated in the Ecodesign Consultation Forum meeting and provided comments.

Guidelines on the application of the Construction Products Regulation (CPR)

The IS PG issued a specific guidance document for intralogistic systems, which come as an annex to the main FEM guide. This guideline helps manufacturers to demonstrate that, in general, intralogistic systems cannot be considered as a construction product and are therefore not affected by the CPR.

Practical guide for a successful intralogistic system project

The PG published a leaflet for customers aiming to provide advice on how to ensure successful and fair cooperation with a system supplier. It gives tips and draws attention to the key aspects for the design of an intralogistic system, the selection of the supplier and the implementation of the final project.

Technical documents

See section Publications, Technical Guidance, subsection Storage and Retrieval Machines

Guidance & positions

- 2016 – Guidance on how to achieve a successful intralogistic systems project: FR, EN, ES, DE

- 2015 – Guidance on the application of the Construction products Regulation to intralogistic systems: EN

- 2014 – FEM IS PG comments on the Commission Working Document on Ecodesign requirements for electric motors and variable speed drives (Lot 30) – 10 November 2014

Statistics

Order Intake (Index) :

| Factsheet 2020 | Factsheet 2019 | Factsheet 2018 |

Structure

|

Frank van Dijck, President (Vanderlande) |

|

Claire Grossmann, Secretary General (FEM) Tel: +32 2 206 68 77 Email: claire[dot]grossmann[at]orgalim[dot]eu |

| Lucas Unger , Technical Secretary (VDMA) Email: lucas[dot]unger[at]vdma[dot]org |